Methods

Why does this work?

-

The spectrum is fundamentally related to the radial distribution function:

The spectrum, \( \chi(k) \), is related to the radial distribution function \( g(r) \) through the following integral: \[ \chi(k) = S_0^2 \int_a^b A(k,r) \frac{1}{r^2} \sin\left(2kr + \delta(k,r)\right) g(r) \, dr \] Where:-

\( S_0^2 \) is the passive electron reduction factor.

\( A(k,r) \) is the photoelectron scattering function, which includes inelastic losses.

\( \delta(k,r) \) is the phase shift of the photoelectron.

\( g(r) \) is the unknown pair distribution function of the nearest neighbors to the X-ray absorbing atoms, describing the probability distribution of interatomic distances.

- Theoretical simulations of EXAFS - the X-ray spectra used in this project- are very accurate, and can be done on any atomic coordinates: Therefore, we can learn the spectrum-structure relationship from a large dataset of simulated spectra and corresponding atomic coordinates, even if the configurations are not physically realistic.

-

There are many possible configurations of atoms, but we can simplify the configuration space by defining a distribution of possible lengths that the interatomic distances can take.

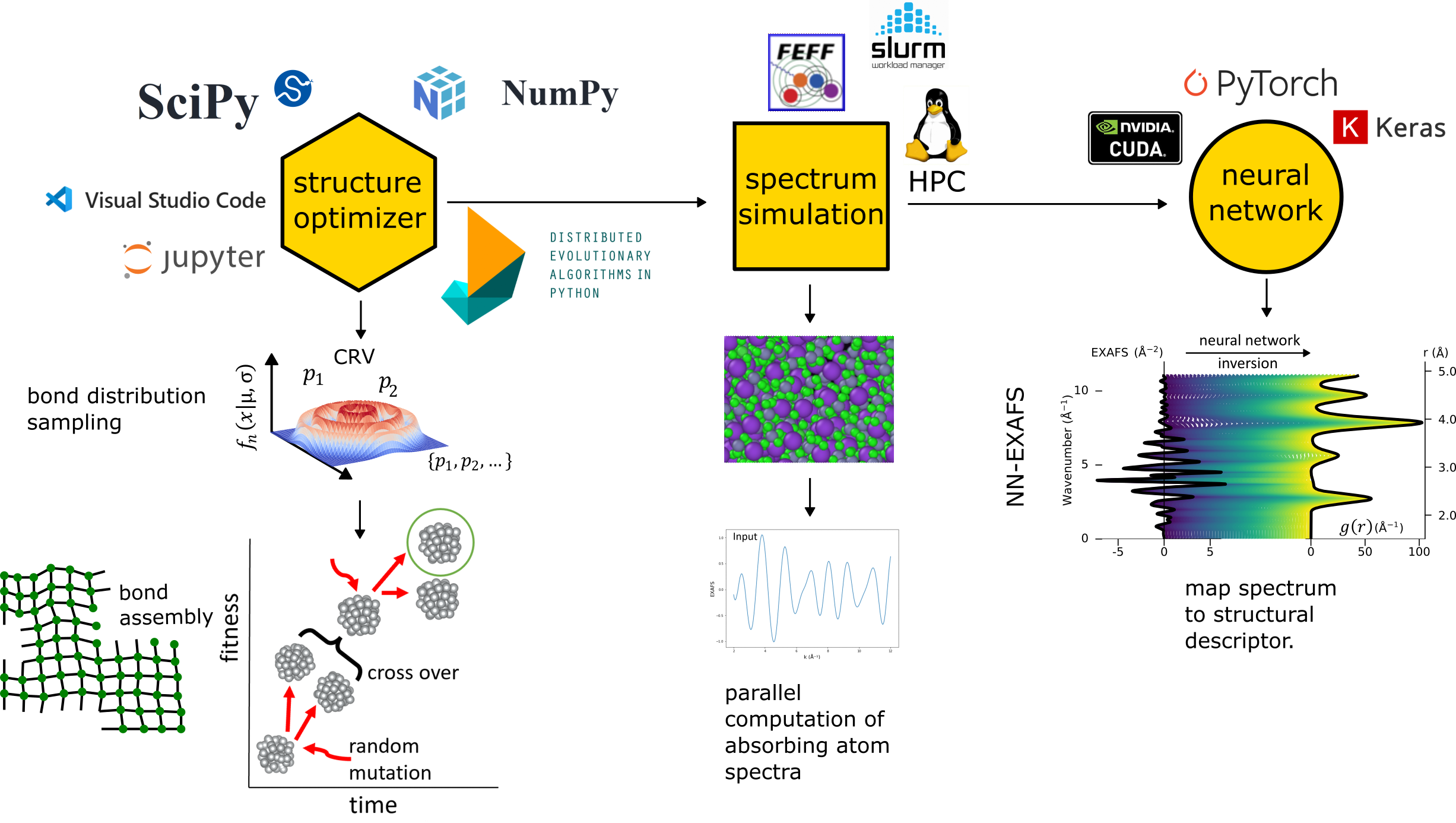

Bond length distributions are defined by absorber-neighbor pair lengths for each coordination shell and for each scatterer type if multiple elements are present. This is described using continuous random variables (CRVs).- A CRV for each shell is denoted as \( v_{n,e} \), where \( n \) represents the neighbor shell index and \( e \) the scattering element.

- These CRVs, collectively referred to as the "macrostate", each follow a probability density function given by: \[ f_n(x | \mu, \sigma) = \frac{1}{\sigma \sqrt{2\pi}} \exp \left(-\frac{(x-\mu)^2}{2\sigma^2}\right) \]

- They are organized into sets \( V_e = \{v_{1,e}, v_{2,e}, \ldots\} \), where \( V_e \) represents the macrostate with adjustable mean \( \mu_n \) and standard deviation \( \sigma_n \).

- To generate structures, \( N_n \) pair-lengths, corresponding to the number of neighbors per shell \( n \), are sampled from each CRV of the macrostate to create a list of absorber-neighbor pairs known as the "microstate".

- Finally, the pairs from the list are assembled into a 3D structural configuration for scattering calculations with FEFF.

-

Once we have a set of bonds, we can assemble them in space with a genetic algorithm.

A genetic algorithm (GA) to creates the 3D structures, employing a customizable fitness function that takes into account constraints on bond lengths and coordination numbers, while also optimizing bond angles. The steps involved in the GA process are as follows:- The fitness function is designed to maximize the minimum pair distance between all atoms, ensuring that atoms are adequately separated in space.

- Since the distance to the central atom is held constant and only the bond angles are modified, the GA maintains spatial separation to prevent atoms from overlapping.

- By iterating through generations, the GA refines the atomic configuration, evolving toward an optimal 3D structure that satisfies the given constraints.